- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

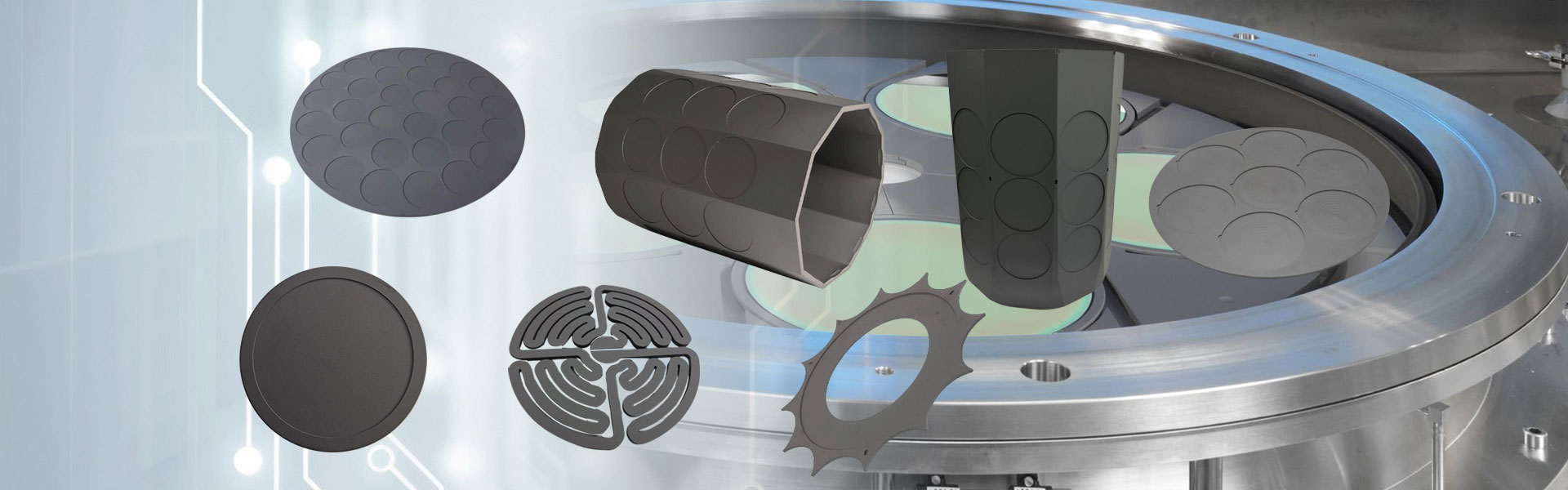

Kina Isostatisk grafit producenter, leverandører, fabrik

- View as

Bronze grafit bøsning

Semicorex bronze grafit bøsning har karakteristika af høj belastningskapacitet, slagfasthed, høj temperatur modstand, stærk selvsmøring evne og kan også modstå erosion og skuring af ætsende væsker. Denne bronzegrafitbøsning er især velegnet til udstyr, der arbejder under komplekse arbejdsforhold, hvor der er oliefrit, højtemperatur-, højbelastnings-, lavhastigheds-, antibegronings-, anti-korrosions- og anti-strålingsmiljø.

Læs mereSend forespørgselSelvsmørende lejer

Semicorex selvsmørende lejer er en type leje, der kombinerer grafitmaterialers selvsmørende egenskaber. De er meget udbredt i industrielle områder med høje smørekrav og komplekse miljøforhold.

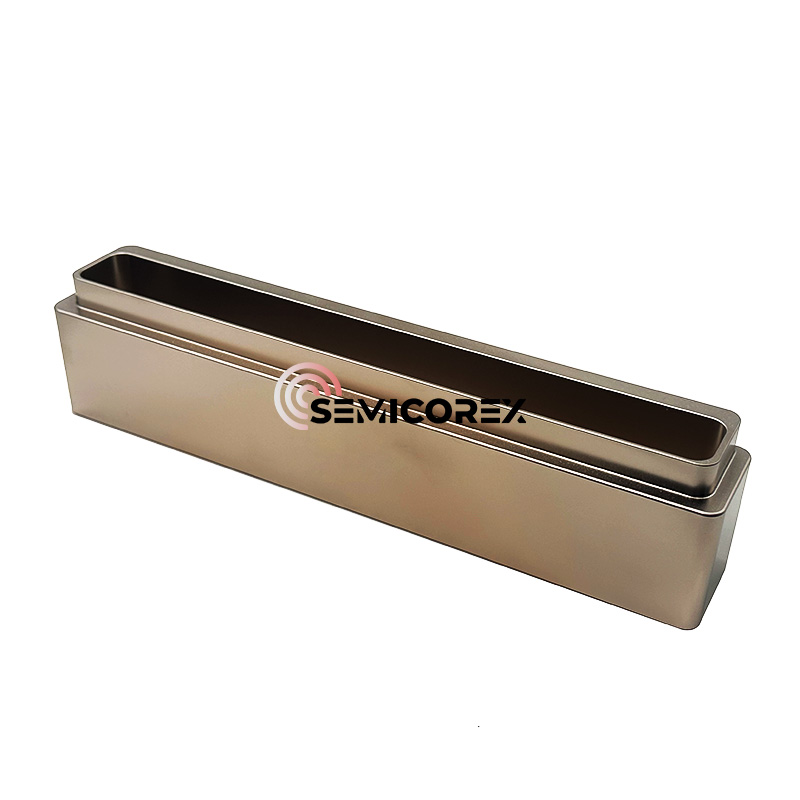

Læs mereSend forespørgselGrafitstangvarmer

Semicorex Graphite Rod Heater er et højtydende varmeelement designet til ensartet høj-temperaturgenerering inde i vakuumovne. Vælg Semicorex for sin ekspertise inden for præcisions-konstruerede grafitløsninger, leverer overlegen termisk stabilitet og langvarig præstation, der er skræddersyet til dine industrielle behov.*

Læs mereSend forespørgselGrafitelektrodestang

Semicorex-grafitelektrodestænger er grafitkomponenter med høj renhed, der bruges som kerneopvarmningselementer i vakuumovne. Vælg Semicorex for uovertruffen materialekvalitet, præcisionsbearbejdning og pålidelig ydelse i vakuummiljøer med høj temperatur.*

Læs mereSend forespørgselGrafit topplader

Semicorex Graphite topplader er præcisions-konstruerede inventar designet til sikker og pålidelig håndtering af varme glasflasker i produktionsmiljøer med høj temperatur. Vælg Semicorex for uovertruffen materialekvalitet, brugerdefinerede bearbejdningsevne og konsekvent ydelse, der er tillid til af førende glasproducenter over hele verden.*

Læs mereSend forespørgselGrafitmuller

Semicorex Graphite Crucibles konstrueret til enestående termisk stabilitet og forureningskontrol i halvlederkrystallvækstprocesser. Vælg vores grafitmuller for uovertruffen renhed, ydeevne og pålidelighed i halvlederkrystallvækst. *

Læs mereSend forespørgsel